About Gates

Gates Corporation Brand Profile

Gates Corporation is a global leader in manufacturing industrial and automotive drive belts, as well as fluid power products. Headquartered in Denver, Colorado, USA, the company was founded in 1911 by John Gates Initially starting with the production of V-belts for automobiles, Gates expanded its business through technological innovation and strategic acquisitions, becoming a leading enterprise in global transmission systems. In 2014, the company was acquired by the British investment firm Blackstone Group but continues to operate independently.

Core products

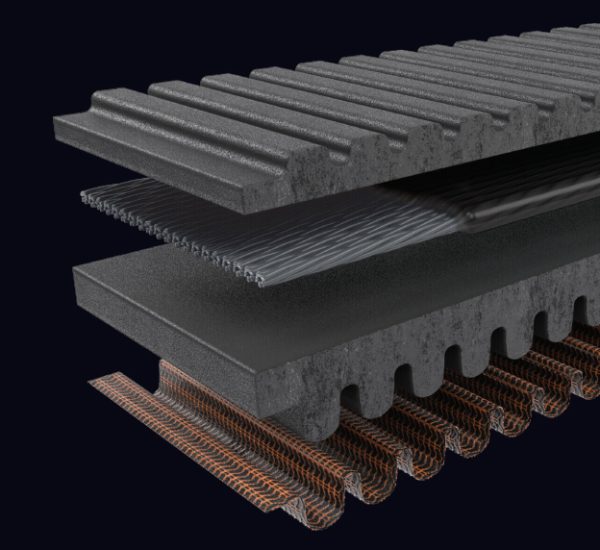

Belts: Timing belts, multi-ridged belts, synchronous belts, V-belts, etc., are widely used in the fields of automobiles, industrial equipment, agricultural machinery, etc.

Technological Advantages

Material innovation: Utilizing reinforcing materials such as carbon fiber and aramid to enhance product durability and efficiency.

Patented technologies: such as the Grounded In Good™ series, emphasizing environmental protection and sustainability.

Testing standards: The product must pass extreme environment tests to ensure reliability under conditions such as high temperature and high pressure.

Advanced pulley design

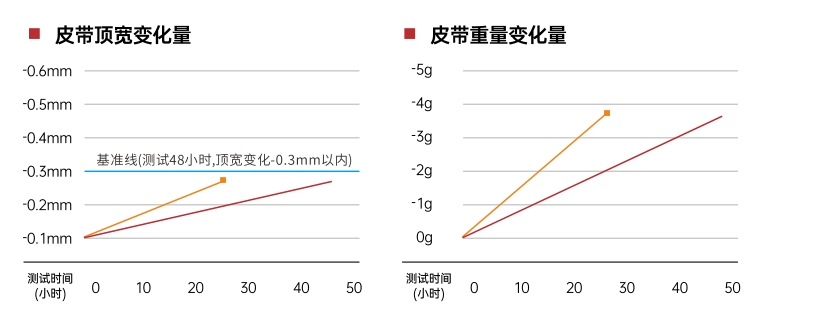

The CENTERTRACK belt drive system has been further optimized in the application of off-road vehicles

The width of the gear disk is reduced (>5mm)

The weight of the gear disk is reduced (up to 10%).

The lifespan of the belt is comparable to that of a standard belt drive system

Cost reduction of gear discs (for medium and high quantities)

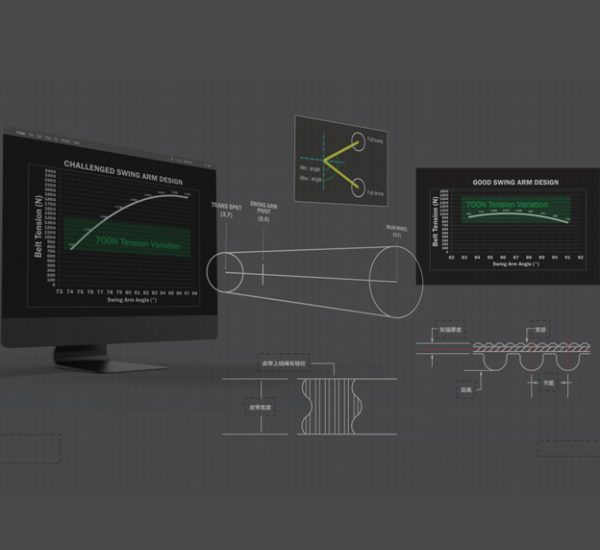

Meet your design requirements

Working with Gates in the early stage of product design can expand your engineering and technical team and enhance your professional experience in transmission, thereby achieving a balance between product performance and cost.

We will start from the following aspects:

How will your product move, operate and run?

What are the requirements of your system for temperature, environment, fuel efficiency, load or power?

What type of services, maintenance and support do you need to meet the market demand?

On this basis, we use Gates’ proprietary software tools to optimize your transmission system design.

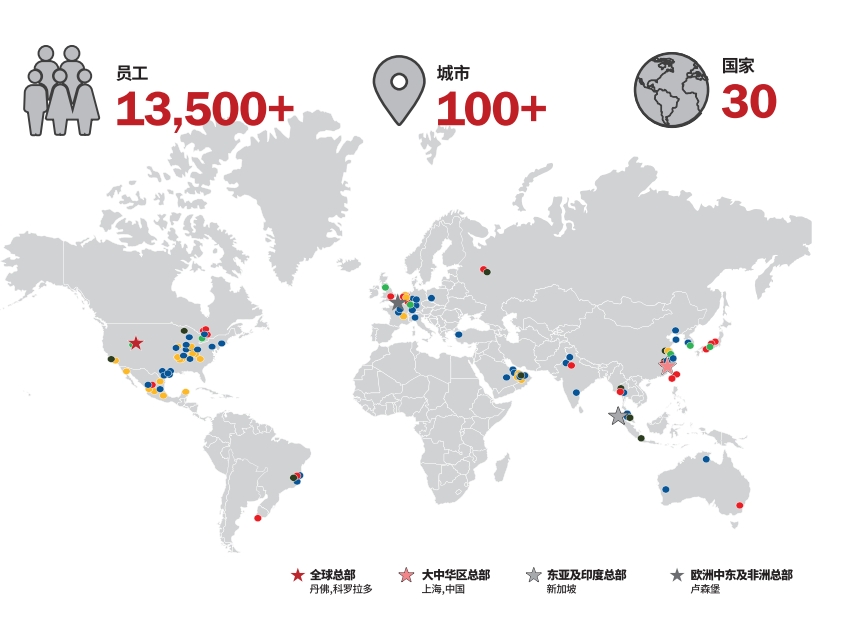

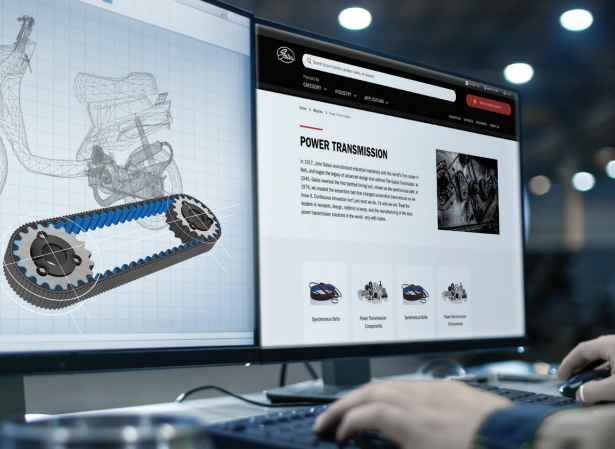

Drive together with Gates

Gates has technical engineering centers and technical sales offices all over the world, providing comprehensive support for your design, manufacturing and after-sales service.

Gates'application research and development capabilities

Strong aging resistance, super long life, fatigue life 200% higher than that of ordinary neoprene products

Super abrasion resistance

Improve wear resistance (quality loss rate) by 50%; The strength of the new generation single-sided tooth products is 10-20% higher than that of general products; Increase the fixed load extension rate by 10%; High modulus rope ensures a significant increase in strength and elongation, providing better static dimensional stability

Ultra wide working environment temperature

High temperature environment: capable of working at an ambient temperature of 110 ° C, short-term resistance to high temperature of 140 ° C. Low temperature environment: capable of working in a low temperature environment of -40 ° C, short-term resistance to low temperature of -60 ° C

Chassis fatigue test

Completed 10000km without any failure

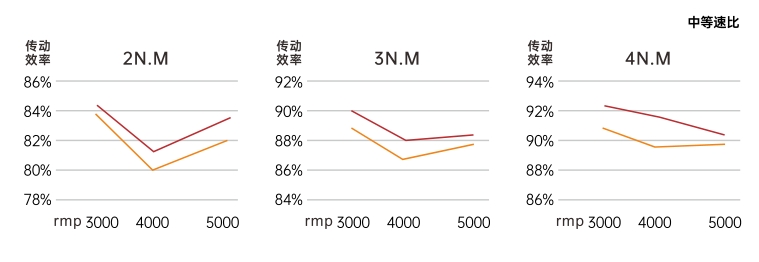

Transmission efficiency test

Test data shows that Gates’ high-efficiency variable speed V-belt transmission efficiency is superior to other brands.

New generation efficient variable speed V-belt

Gates has developed a new generation of POWERLINK @ efficient variable speed V-belt D-EX62 double-sided toothed variable speed V-belt, and completed a series of static and dynamic tests at Gates Asia R&D Center (Japan).

Gates enters the Chinese market

First manufacturing plant established

Taiwan office opens

Shanghai plant begins operations

Second Suzhou plant established

Joint venture plant launched in Yantai

Engineering Service Center commences operations

Changzhou plant established

R&D Center initiated.

Gates Greater China regional headquarters established.

Contact Us

Our products have obtained certificates issued by quality inspection agencies such as ISO9901, SGS, CE, etc. Our products are sold to various countries around the world and look forward to working with you.

+86-17268209580

[email protected]

Shanghai, China